The Caliper Log is a tool for measuring the diameter and shape of a borehole. It uses a tool which has 2, 4, or more extendable arms. The arms can move in and out as the tool is withdrawn from the borehole, and the movement is converted into an electrical signal by a potentiometer.

In the two arm tool, the borehole diameter is measured. This is shown in track 1 of the master log together with the bit size for reference. Borehole diameters larger and smaller than the bit size are possible. Many boreholes can attain an oval shape after drilling. This is due to the effect of the pressures in the crust being different in different directions as a result of tectonic forces. In oval holes, the two arm caliper will lock into the long axis of the oval cross section, giving larger values of borehole diameter than expected. In this case tools with more arms are required.

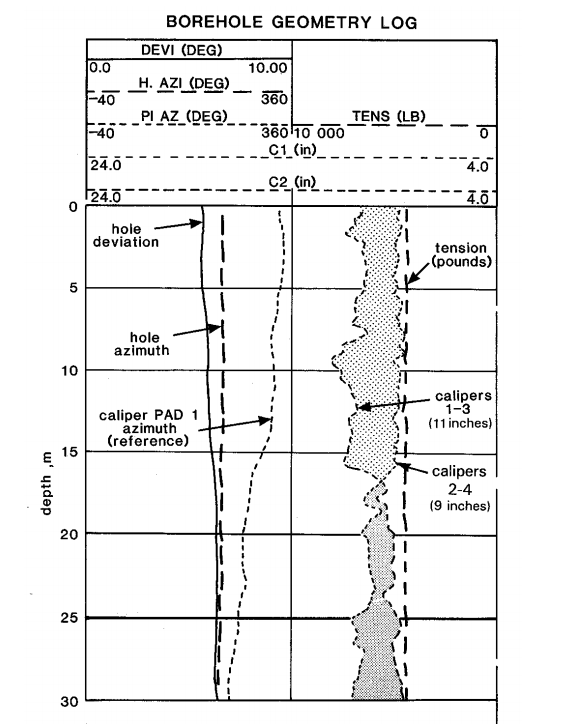

In the 4 arm (dual caliper) tool, the two opposite pairs work together to give the borehole diameter in two perpendicular directions. An example of a 4 arm tool is the Borehole Geometry Tool (BGT). This has 4 arms that can be opened to 30 inches (40 inches as a special modification), and give two independent perpendicular caliper readings. The tool also calculates and integrates the volume of the borehole and includes sensors that measure the direction (azimuth) and dip of the borehole, which is useful in plotting the trajectory of the borehole.

In the multi-arm tools, up to 30 arms are arranged around the tool allowing the detailed shape of the borehole to be measured.

Some of the other tools in this course have sensors attached to pads that are pressed against the borehole wall. The pressing device is also a form of caliper, and so caliper information can sometimes also be obtained from these tools.

Log Presentation

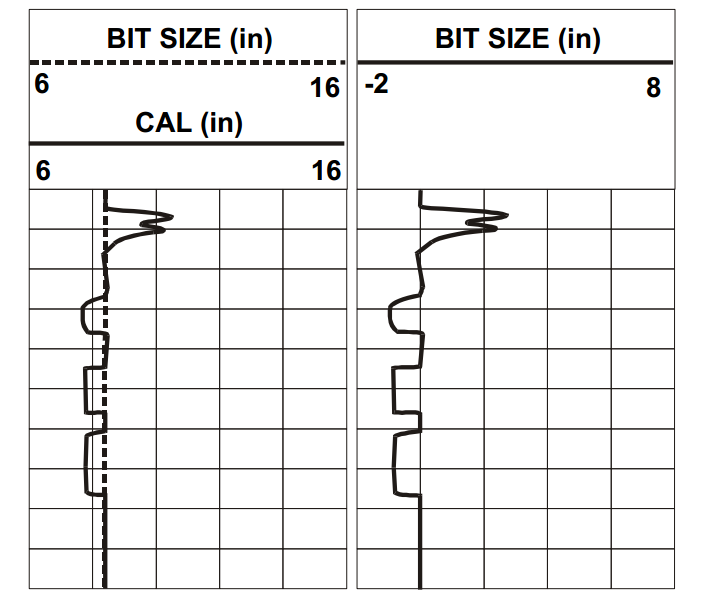

The caliper logs are plotted in track 1 with the drilling bit size for comparison, or as a differential caliper reading, where the reading represents the caliper value minus the drill bit diameter. The scale is generally given in inches, which is standard for measuring bit sizes.

The 4 arm (or dual caliper) tools are presented in a range of formats. Note that data from the caliper pairs are shown together, and that they are different indicating an oval hole. Also the tool rotates in the hole (the pad 1 azimuth P1AZI changes). The hole azimuth is reasonably constant at HAZI»180o, and the dip is almost vertical (DEVI is about 0o). The ticks represent borehole volume. This information is useful to estimate the amount of drilling mud in the borehole, and to estimate the amount of cement required to case the hole. There are engineering approximation formulas to calculate both of these from caliper data.

Simple Caliper Interpretation

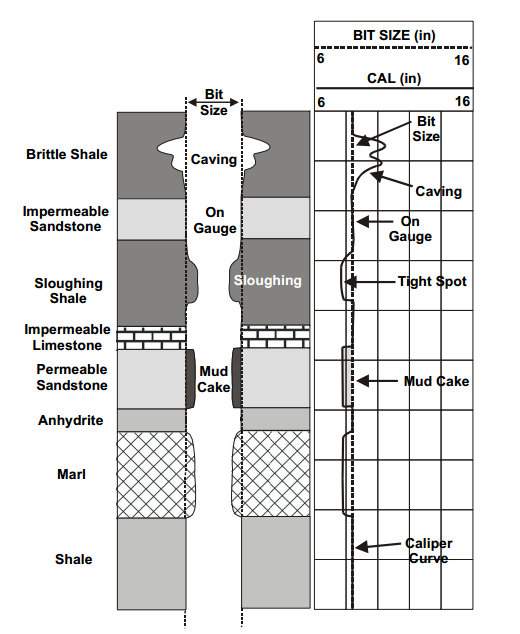

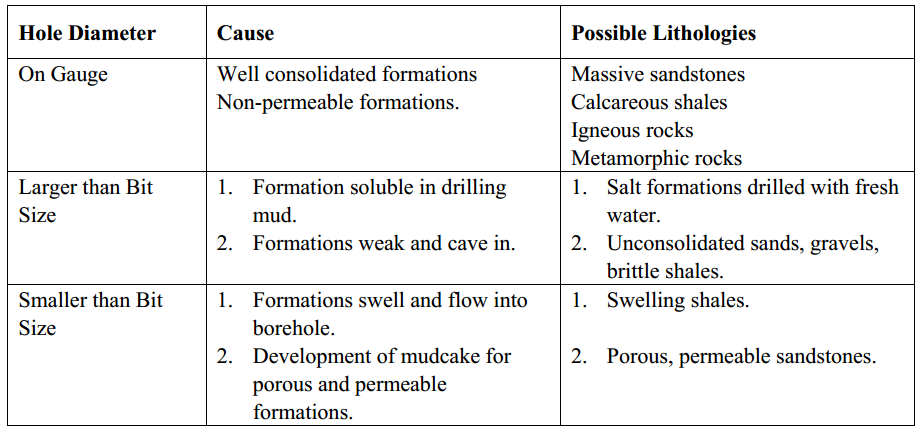

Figure 3 shows a schematic hole with caliper information, and Table 1 describes the main influences on caliper values. Note that when a hole is the same diameter as the bit-size it is called on gauge.

Fig. #3 Typical caliper responses to various lithologies.

Table #1 Factors influencing caliper responses.

%20(1).png)