Wellbore instability is experienced mainly in shale sections, induced by either high stress concentration or physical-chemical interactions of the drilling fluid with the shale, or a combination of both;

1. Mechanical stress-induced wellbore stability

2. Chemical related instability

- a) Time-dependent drilling fluid-shale interaction

- b) Time dependent water interaction with chalk, limestone, anhydrite, gypsum etc

Mechanical related stability problems are, besides minor erosion from turbulent flow and drill string interaction with the wall, governed by wellbore stresses. It is related to the vertical stresses created by the overburden. The overburden results in vertical compression / deformation, which create compressional stresses in the horizontal direction. Mechanical wellbore instability is a topic covered in courses of rock physics. In this book, mechanical wellbore instability will merely be pointed at, since it is inter-related to its chemical counterpart; water interaction with the sediments will have a negative influence on mechanical stability.

Chemical stability of the wellbore is related to water and its complex interaction with shale. The time dependency is related to the time it takes for water to be transported into the shale.

Reaction with chalk/limestone/anhydrite is related to dissolution of dissolvable material. Chalk, limestone and salt are all ionic compounds. Dissolution of them can lead to several problems:

- Flocculation of the colloidal phase of drilling fluid; clay or polymers (increasing viscosity) or aggregation of clay after ion-exchange (decreased viscosity)

- High solids content (disintegration of weakened cuttings)

- Hole enlargement (washout of weakened wall)

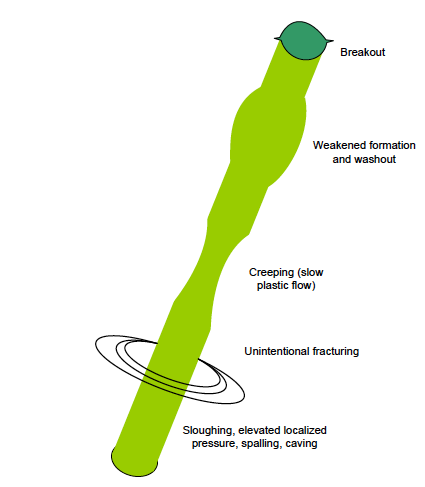

Wellbore instability problems take many forms, and the most frequent ones are pointed out in Figure 1.

Wellbore instability problems take many forms, and the most frequent ones are pointed out in Figure 1.

%20(1).png)