Types of Oil Rigs

There are many different types of oil rigs, but they can be broadly classified into two categories: onshore and offshore. Onshore rigs are used to drill wells on land, while offshore rigs are used to drill wells in water.

Some of the most common types of oil rigs include:

- Jackup rigs: These rigs have three legs that can be raised and lowered to allow the rig to operate in different depths of water. Jackup rigs are typically used in shallow water, up to about 400 feet deep.

- Semisubmersible rigs: These rigs have six or eight legs that are attached to pontoons that float on the surface of the water. Semisubmersible rigs can operate in deeper water, up to about 3,000 feet deep.

- Drill ships: Drill ships are specialized ships that have been converted into oil rigs. They can operate in very deep water, up to about 12,000 feet deep.

Components of a Drilling String

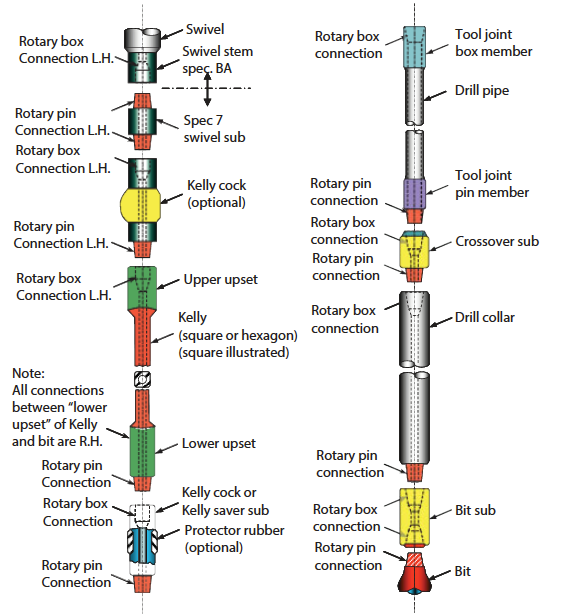

The drilling string is a long, hollow pipe that is used to transmit torque and drilling fluid to the drill bit. It is made up of a number of different components, including:

- Drill pipe: The drill pipe is the main component of the drilling string. It is made up of long, hollow sections that are connected together by tool joints.

- Drill collars: Drill collars are heavy-walled pipes that are added to the bottom of the drilling string to provide weight on bit and help to keep the drill string straight.

- Bottom hole assembly (BHA): The BHA is a group of tools that are attached to the bottom of the drilling string. It includes the drill bit, as well as other tools such as stabilizers, reamers, and jars.

Functions of the Drilling String

The drilling string has a number of important functions, including:

- Transmitting torque to the drill bit: The drilling string is used to transmit torque from the rotary table or top drive to the drill bit. This torque is used to rotate the drill bit and break up the rock formation.

- Circulating drilling fluid: The drilling string is used to circulate drilling fluid from the surface to the drill bit and back. Drilling fluid is used to cool and lubricate the drill bit, remove cuttings from the wellbore, and control well pressure.

- Providing weight on bit: The weight of the drilling string helps to push the drill bit into the rock formation.

Conclusion

The drilling string is a vital component of any oil rig. It is responsible for transmitting torque to the drill bit, circulating drilling fluid, and providing weight on bit. Without the drilling string, it would not be possible to drill oil and gas wells.

Additional Information

In addition to the basic components listed above, the drilling string may also include a number of other tools, such as:

- Mud motors: Mud motors are devices that use the flow of drilling fluid to generate torque. They can be used to rotate the drill bit independently of the rotary table or top drive.

- Measurement while drilling (MWD) tools: MWD tools are used to collect data about the wellbore while drilling. This data can be used to optimize the drilling process and make better decisions about well placement.

- Logging tools: Logging tools are used to collect data about the rock formations in the wellbore after drilling has been completed. This data can be used to identify potential oil and gas reservoirs.

The drilling string is a complex and sophisticated system that plays a vital role in the oil and gas industry.

%20(1).png)