Two possible solutions using the pendulum and the packed hole concepts.

Pendulum Theory

In the early 1950s, Woods and Lubinski collaborated in mathematical examination of the forces on a rock bit when drilling in an inclined hole. In order to make their calculations, they made three basic assumptions:

1. The bit is like a ball and socket joint, free to turn, but laterally restrained.

2. The drill collars lie on the low side of the hole and will remain stable on the low side of the hole.

3. The bit will drill in the direction in which it is pushed, not necessarily in the direction in which it is aimed.

Consequently, the forces which act upon the bit can be resolved into:

1. The axial load supplied by the weight of the drill collars.

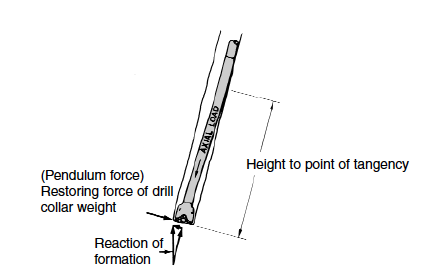

2. The lateral force — the weight of the drill collar between the bit and the first point of contact with the wall of the hole by the drill collar (pendulum force). Pendulum force is the tendency of the unsupported length of drill collar to swing over against the low side of the hole because of gravity. It is the only force that tends to bring the hole back toward vertical (see Figure No. 1).

Fig.No:1

Fig.No:1

3. The reaction of the formation to these loads may be resolved into two forces — one parallel to the axis of the hole and one perpendicular to the axis of the hole.

This work made it possible to utilize gravity as a means of controlling change in the hole angle. Special tables were prepared to show the necessary weight for the bit to maintain a certain hole angle. These tables also show the proper placement of a stabilizer to give the maximum pendulum force and the maximum weight for the bit. The effects of using larger drill collars can also be determined.

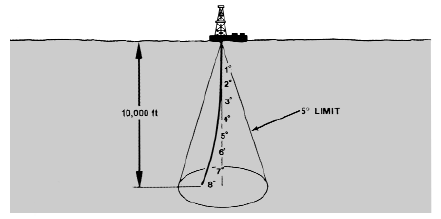

Packed Hole Theory

Most people today use a packed hole assembly to overcome crooked hole problems and the pendulum is used only as a corrective measure to reduce angle when the maximum permissible deviation has been reached. The packed hole assembly is sometimes referred to as the “gun barrel” approach because a series of stabilizers is used in the hole already drilled to guide the bit straight ahead. The objective is to select a bottom-hole assembly to be run above the bit with the necessary stiffness and wall contact tools to force the bit to drill in the general direction of the hole already drilled. If the proper selection of drill collars and bottom-hole tools is made, only gradual changes in hole angle will develop. This should create a useful hole with a full-gage and smooth bore, free from doglegs, key seats, offsets, spirals and ledges, thereby making it possible to complete and produce the well (see Figure No. 2).

Fig.No: 2

Fig.No: 2

%20(1).png)