In the realm of oil and gas exploration, as well as various drilling operations, the drill string stands as a vital element in the extraction process. Comprising a series of interconnected components, the drill string serves as the conduit for transmitting the drilling force and torque from the surface rig to the drill bit deep below the Earth's surface. This article delves into the crucial components of the drill string, highlighting their individual functions and collective significance in successful drilling endeavors.

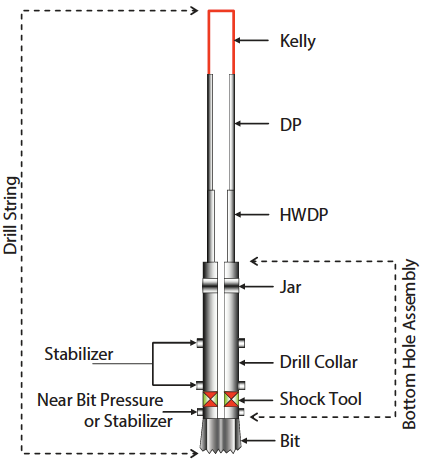

1. Drill Pipe:

At the forefront of the drill string is the drill pipe, a tubular section that provides a conduit for drilling fluid to circulate from the surface to the drill bit and back. Constructed from high-strength steel, drill pipes are threaded at both ends to facilitate connection with other components. They endure substantial stress and pressure, necessitating robust materials and careful design.

2. Drill Collars:

Directly below the drill pipe lie the drill collars, heavy cylindrical components that add weight to the drill bit. This added weight enables effective penetration of the rock formations. Drill collars are typically made from solid bars of steel and are designed to withstand bending and torsional stress.

3. Heavyweight Drill Pipe:

Sitting between the drill pipe and the drill collars, heavyweight drill pipe combines the properties of both. It is lighter than a drill collar but heavier than a regular drill pipe. This component aids in achieving a balanced transition of weight between the upper and lower sections of the drill string, reducing the risk of buckling.

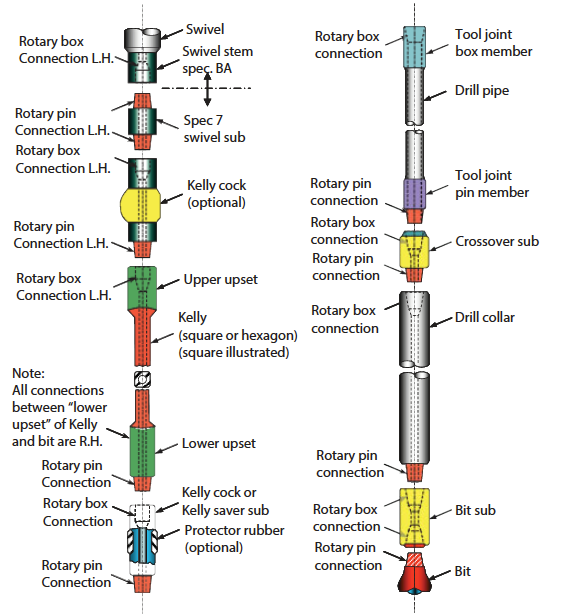

4. Joints and Connections:

Joints and connections are crucial interfaces between drill pipe segments and other components. The threaded connections must be precisely machined to ensure a secure fit that can withstand the immense forces encountered during drilling. The threads are often coated with a lubricant and tightened using specialized tools to prevent "thread galling," a form of excessive friction that could compromise the integrity of the connections.

5. Subs and Accessories:

Subs, short for "subassemblies," are intermediary components that facilitate the connection between mismatched threads or sizes of various components. Additionally, various accessories such as stabilizers and reamers may be attached to the drill string to aid in steering the drill bit and maintaining the wellbore's diameter.

6. Drill Bit:

At the lowermost end of the drill string is the drill bit, the component responsible for breaking and crushing rock formations. Drill bits come in various designs tailored to specific geological conditions. The drilling fluid, pumped through the drill string, helps cool and lubricate the bit, while also carrying the cuttings back to the surface.

The drill string serves as the backbone of drilling operations, enabling the extraction of valuable resources from beneath the Earth's surface. Each component plays a vital role in the overall efficiency and success of the drilling process. From the sturdy drill pipe to the precisely threaded connections, the interplay of these components ensures safe and productive drilling, underscoring the critical importance of a well-designed and meticulously maintained drill string.

%20(1).png)