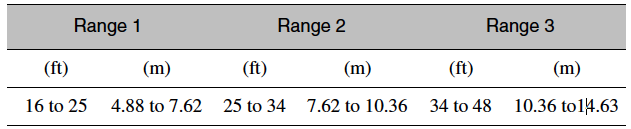

The lengths of casing joints vary. In the manufacture of seamless casing, it all depends on the size of the billet used in the process. Usually, there is some difference in weight of the billets, and this results in some variation in the length of the final joints. One could cut all the joints to the same length, but that would be a needless expense and, in fact, would not be desirable. (Wire line depth correlation for perforating and other operations in wells usually depends on an electric device to correlate the couplings with a radioactive formation log; so if all the joints are the same length, it can cause errors in perforating or packer setting depths.) For ERW casing, it is much easier to make all of the joints the same length, but there may still be some waste if that is done. Even if the joints vary in length, they need to be sorted into some reasonable ranges of lengths for ease of handling and running in the well. Three ranges of length are specified by API Recommended Practices 5B1 (1999), Ranges 1, 2, and 3 (see Table below).

Most casing used today is in either Range 2 or 3, with most of that being Range 3. Range 1 is still seen in some areas where wells are very shallow, and the small rigs that drill those wells cannot handle longer pipe.

Length Ranges of Casing (API RP 5B1, 1999)

%20(1).png)